- +971-04-327-7068

- info@smasterdubai.com

U pipe collectors are a type of solar thermal collector that are commonly used to heat water or air for various applications. They are also known as heat pipe collectors or heat exchanger collectors.

These collectors are designed to absorb solar radiation and convert it into heat energy, which can then be used for space heating, hot water production, and other industrial and commercial applications. U pipe collectors are characterized by their high efficiency, low maintenance requirements, and reliable performance.

In this article, we will discuss the design, working principle, applications, advantages, and disadvantages of U pipe collectors, as well as their maintenance and repair requirements.

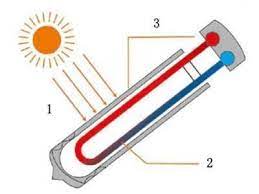

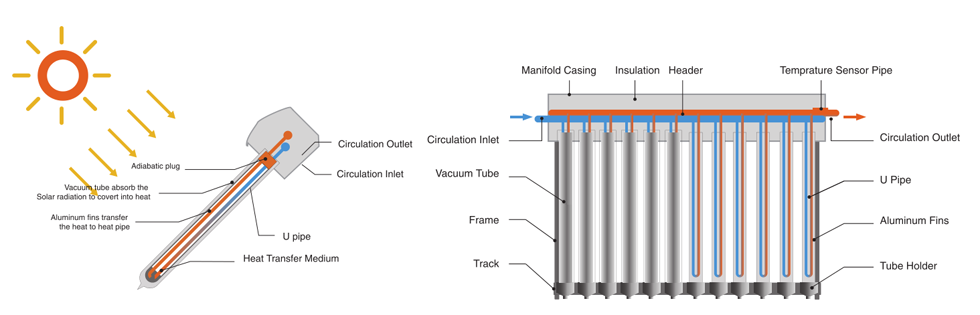

The design of U pipe collectors is relatively simple, but highly effective. These collectors consist of a series of parallel pipes, usually made of copper or aluminum, which are arranged in a U-shape. The pipes are coated with a highly absorptive coating, such as a selective surface, to maximize their solar absorption.

The U-shaped pipes are typically enclosed in a glass or plastic cover, which helps to trap the solar radiation and prevent heat loss. The cover is usually designed to be transparent to allow maximum solar radiation to reach the pipes.

Inside the U-shaped pipes, a fluid, such as water or antifreeze, circulates. As the solar radiation is absorbed by the pipes, the fluid inside them is heated and circulated through a heat exchanger, where the heat is transferred to a secondary fluid, such as water or air. The heated fluid can then be used for space heating, hot water production, or other industrial or commercial applications.

The working principle of U pipe collectors is based on the thermosiphon effect, which is the natural circulation of fluid due to differences in temperature and density. When solar radiation is absorbed by the U-shaped pipes, the fluid inside them is heated and becomes less dense than the cooler fluid in the bottom of the collector. This causes the heated fluid to rise to the top of the collector and flow through the heat exchanger.

As the heated fluid passes through the heat exchanger, it transfers its heat to a secondary fluid, such as water or air, which is then used for space heating, hot water production, or other industrial or commercial applications. The cooled fluid then returns to the bottom of the collector and the process repeats.

The U-shaped design of the pipes allows for maximum exposure to solar radiation, which increases their efficiency and heat output. The fluid inside the pipes is continuously circulated, which ensures that the heat is transferred efficiently and effectively.

U pipe collectors can operate in a wide range of temperatures and weather conditions, and their performance is generally very reliable and consistent. They are highly efficient at converting solar radiation into heat energy, which makes them an attractive option for various applications, including residential, commercial, and industrial heating systems.

There are two main types of U pipe collectors: glazed and unglazed.

Glazed U pipe collectors have a transparent cover made of glass or plastic that covers the top of the collector to protect the pipes and absorbent material from the elements. The glazing also allows for more solar radiation to be absorbed by the pipes, which increases their efficiency. Glazed U pipe collectors are typically used in colder climates where there is less solar radiation available, as they are more effective at trapping heat.

Unglazed U pipe collectors do not have a transparent cover and rely solely on direct solar radiation to heat the fluid inside the pipes. They are typically used in warmer climates where there is ample solar radiation available, as they are less effective at trapping heat and can lose heat due to convection and conduction. However, they are generally less expensive than glazed U pipe collectors and require less maintenance.

Both types of U pipe collectors can be used for various applications, including space heating, hot water production, and pool heating, among others. The specific type of collector chosen will depend on factors such as climate, heating requirements, and budget.

U pipe collectors can be used in a variety of applications, including:

Space heating: U pipe collectors can be used to provide heat to buildings, such as homes, offices, and schools. The heated fluid from the collectors is circulated through a heat exchanger and used to heat the air or water that is then distributed throughout the building.

Hot water production: U pipe collectors can be used to heat water for domestic or industrial use, such as for showers, dishwashers, and washing machines. The heated fluid from the collectors is circulated through a heat exchanger and used to heat the water, which is then stored in a tank.

Pool heating: U pipe collectors can be used to heat swimming pools, allowing for longer swimming seasons and increased comfort for swimmers. The heated fluid from the collectors is circulated through a heat exchanger and used to heat the water in the pool.

Industrial process heating: U pipe collectors can be used for industrial process heating, such as in manufacturing and food processing facilities. The heated fluid from the collectors is circulated through a heat exchanger and used to heat the materials or products being processed.

U pipe collectors are a versatile and efficient technology for providing heat energy for various applications, and they can be customized to meet the specific heating requirements of different applications.

Advantages of U pipe collectors include:

High efficiency: U pipe collectors are designed to maximize the absorption of solar radiation, making them highly efficient in converting sunlight into heat energy.

Versatility: U pipe collectors can be used for a variety of applications, from space heating to hot water production to industrial process heating.

Durability: U pipe collectors are made from materials that are durable and able to withstand harsh weather conditions, making them a long-lasting investment.

Low maintenance: U pipe collectors require very little maintenance, as they do not have any moving parts and are not prone to wear and tear.

Disadvantages of U pipe collectors include:

Cost: U pipe collectors can be expensive to install, especially for larger applications, such as for industrial process heating.

Climate dependent: The effectiveness of U pipe collectors is dependent on the availability of solar radiation, so they may not be as effective in areas with limited sunlight or in colder climates.

Space requirements: U pipe collectors require a significant amount of space to install, so they may not be feasible for smaller buildings or sites with limited space.

Overall, the advantages of U pipe collectors often outweigh the disadvantages, making them a popular and effective technology for solar heating applications.

U pipe collectors are one type of solar collector used for solar heating applications. Here is a comparison with other types of solar collectors:

Flat plate collectors: Flat plate collectors are the most common type of solar collector used for domestic hot water systems. They are relatively inexpensive and have a simple design, but they are less efficient at capturing solar energy compared to U pipe collectors.

Evacuated tube collectors: Evacuated tube collectors are similar to U pipe collectors in that they use a series of tubes to absorb solar radiation. However, they are typically more expensive and have a more complex design, which can make them more difficult to install and maintain.

Parabolic trough collectors: Parabolic trough collectors are used primarily for large-scale solar thermal power plants. They use curved mirrors to focus sunlight onto a receiver tube, which then heats a fluid to produce steam for power generation. While they are highly efficient, they are also very expensive and require a significant amount of space to install.

Overall, the choice of solar collector will depend on the specific application and the site conditions. U pipe collectors offer a good balance of efficiency, versatility, and cost-effectiveness, making them a popular choice for a wide range of solar heating applications.

Like all mechanical systems, U pipe solar collectors require periodic maintenance and repairs to ensure they continue to operate at optimal performance levels. Here are some maintenance and repair considerations for U pipe solar collectors:

Cleaning: Over time, dust and debris can accumulate on the surface of the collector, reducing its efficiency. To keep the collector operating at peak performance, it should be cleaned periodically using a soft-bristled brush or a low-pressure water spray.

Inspecting for leaks: Leaks in the U pipe collector can reduce its efficiency and cause damage to the system. Inspect the collector regularly for signs of leaks, such as wet spots or discoloration on the collector surface. If a leak is found, the damaged section of the collector should be repaired or replaced.

Checking fluid levels: The U pipe collector typically contains a heat transfer fluid that is circulated through the pipes. Over time, the fluid level can drop due to evaporation or leaks. Check the fluid level in the collector periodically and top it up as needed.

Inspecting the piping: The pipes in a U pipe collector can be damaged by freezing, excessive heat, or physical impact. Inspect the piping regularly for signs of damage, such as cracks or deformations. Any damaged sections should be repaired or replaced as needed.

Checking the mounting hardware: The U pipe collector is typically mounted on a support structure that is anchored to the roof or ground. Over time, the mounting hardware can loosen, causing the collector to shift or become unstable. Inspect the mounting hardware periodically and tighten any loose bolts or brackets.

By following these maintenance and repair considerations, U pipe solar collectors can continue to operate at peak performance levels for many years. It is recommended that the system be inspected and serviced by a qualified technician at least once a year to ensure optimal performance and longevity.

U pipe solar collectors are a popular type of solar thermal collector that can be used for a variety of applications, such as hot water generation, space heating, and industrial process heat. They are designed to be efficient, durable, and easy to maintain, making them an attractive option for homeowners and businesses looking to reduce their energy costs and carbon footprint.

While U pipe collectors offer many benefits, they also require regular maintenance and repairs to ensure they continue to operate at optimal performance levels. By following the maintenance and repair considerations outlined above, users can maximize the lifespan and efficiency of their U pipe solar collectors, providing reliable and sustainable energy for years to come.

WhatsApp us